Experiment Name: Study on Round Knife Cutting Machine

Introduction

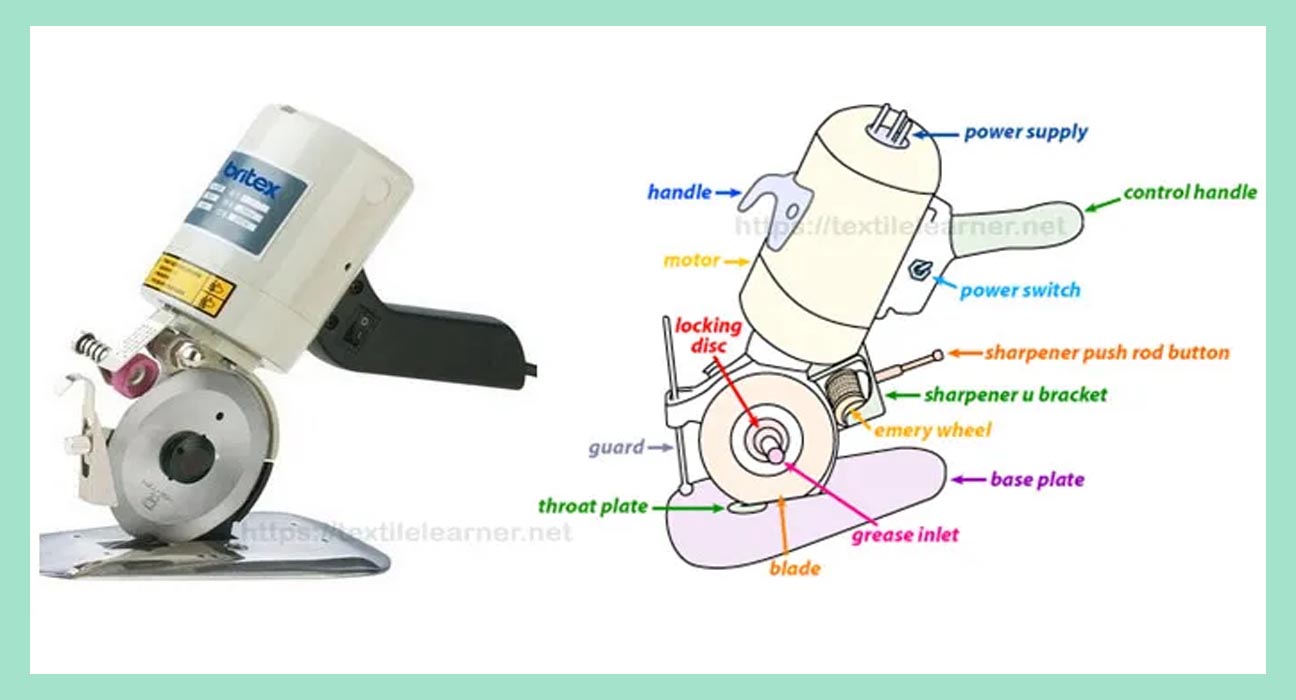

This machine is called round knife cutting machine because its cutter is round but slightly octagonal in shape. It is also called rotary knife cutting machine. This machine is small in size, flexible and used for small production. It is also a popular cutting machine.

Round blade cutting machines are used to cut large and medium-size components of simple shape from low-fabric spreads or to cut single articles from one or two material plies. The machine is moved along the cut contours, while the fabric spread remains in a fixed position.

Round-knife machines are the most effective for cutting slippery materials as the rotary movement of the knife ensures the continuous compression of the fabric plies. Round-knife cutters are lighter (between 3 and 11 kg) than straight knife cutting machines and are therefore easier to move.

Round Knife Cutting Machine

Machine Specification:

Brand Name: JBL

Origin: China

Knife size: 4”

Lay Capacity: 2”-2.5”

RPM: 2000-2500

Main Parts:

- Motor

- Power Cord

- Handle

- Sharpener Set

- Pressure Foot/ Knife Guard/ Blade Guard

- Knife/ Blade

- Base Plate

Round Knife Cutting Machine

Features:

- Knife Size 2-8 inches

- Lay Capacity 1.25-4.5 inches

- 7-16 Kg

- Height varies

- All types of Fabric

- Curvy/ Smaller pieces of pattern can be cut very easily.

- Rpm 900-3000

- Steel Knife, Teflon coated

- Knife shape round or octagonal

- The machine is movable and the fabric is fixed while cutting.

- The circular motion of the knife

- Difficulty cutting at a perfectly 90-degree angle.

Advantages

- Suitable for cutting single-ply as well as multilayer (say 20-30layers).

- Easy to handle and operate.

- Suitable for small-scale cutting.

- Suitable for gentle curve line cutting.

- To cut the larger part of the garments.

- With the same r.p.m. its efficiency is 10 times greater than the straight knife.

Disadvantages

- Very low r.p.m. and knife height.

- A manual grinder is used.

- Low productivity since few lay can be cut.

- Difficult to cut small components and high curve lines.

- Not suitable for large production.

- Lubrication is manually done.

Round Knife Cutting Machine

Conclusion

It’s useful for gentle curve line cutting, big parts cutting, cutting out fabric blocks from lay, and small-scale cutting. It’s normally used for small production.