Before knowing the Process Sequence of Garment Manufacturing we need to be clear about some basic key phrases. Such as;

Apparel/ Clothing/Garment:

Garment means the fabric which is taking different shapes as per the body measurements of human beings by cutting & sewing. It is used for protection, decoration & identification.

Basic Function of Clothing/Garment:

- To protect the human body from different Environmental conditions.

- To lead a civilized life.

- Have a feeling of comfort.

- To increase attractiveness.

- To save the human body from the adverse or unusual situations.

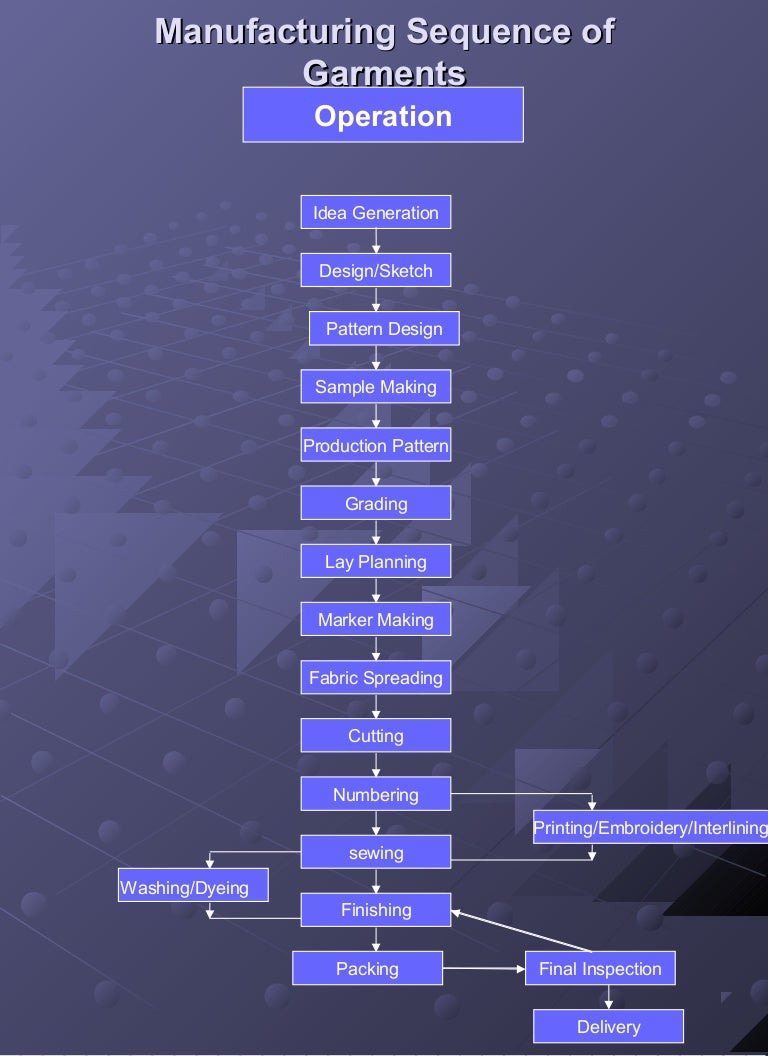

Process Sequence of Garment Manufacturing

Process Sequence of Garment Manufacturing

| Operation | Job | Method |

| Design or Sketch | Sketch of a particular garment including its design features is essential on paper

Sample garment are produced and verified with its sketch |

Could be done manually or with the software, popular software is kaledo style of Lectra |

| Pattern design | Hard paper copy of each component of a garment of exact size and shape Pattern also include seam allowance, shrinkage of the fabric trimming allowance, dart etc. | Could be done manually or with the help of a computer |

| Sample making | Patterns are used to cut fabric Cut components are assembled to make a sample garment | Usually done by a very efficient and technically sound person |

| Production pattern | Pattern of the approved sample garments are used to make production pattern.

Minor modification may be done on production pattern if buyer has any advice. |

Could be done manually or with the help of a computer |

| Grading | Pattern grading is the process of turning base size or sample size patterns into additional sizes using a size specification sheet or grading increments. | Could be done manually or with the help of software |

| Marker making | All the pattern pieces for the required sizes are arranged in the paper in such a way so that required number of different size garments may be produced with minimum

fabric wastage Used for calculation of exact consumption of fabric |

Could be done manually and with the help of computer |

| Spreading | Process of arranging fabric on the cutting table to cut.

Height of the lay is limited up to maximum six inches. |

Could be done manually or mechanically |

| Cutting | Normally straight knife cutting machine is used to cut out the garment component as per exact dimension of the pattern.

Care must be taken to avoid cutting defects. |

By using a straight knife machine or modern cutting machine |

| Sorting and bundling | Sort out the fabric according to size & for each size make individual bundle. | Done Manually |

| Printing and

embroidery |

These two process are done before sewing. Both printing and embroidery requires flat form of the fabric for processing | Could be done by manually or using modern machines |

| Sewing | Cut pieces of fabric is assembled in this process Most important section of garment manufacturing unit.

Vertical line balancing is done to produce a specific garment. Numbers of sewing machine per line varies from 15 to 60 depending on style of the garment. |

Done by using modern sewing machine |

| Finishing | After passing through inspection table, all garments are normally go through thread sucking machine to remove floating dirt, measured and ironed/pressed to remove unwanted crease and to improve smoothness. | Done by using modern machine |

| Packing | Finished garments are folded as per buyer’s instruction, inserted into the poly bags and cartooned as advised by the buyer. | Done manually |

| Inspection (Final) | Final random inspection (FRI) is usually done by the buyer or the representative of buyer.

After completion of packing FRI is conducted. AQL is applied in FRI as advised by the buyer.

Usually AQL 2.5 is applied in Apparel inspection. Goods are delivered to the shipping agents if goods are passed in the FRI.

Goods are sent to the finishing section for repair/amend if goods are failed in the FRI. |

Done manually |