In this article, we have focused on CRE vs CRL or the Difference between CRE and CRL, or distinction between CRE and CRL.

CRL stands for Constant Rate of Loading and CRE stands for Constant Rate of Elongation. Before knowing the differences we need to have a clear crystal knowledge about them.

CRE vs CRL

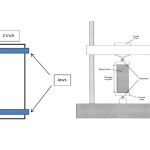

What is CRL or Constant Rate of Loading?

A specimen is gripped between two jaws; the top jaw which is fixed and the bottom jaw which is moveable. The load on the specimen is initially zero but increases at a constant rate.

Adding a constant rate of water in a container that is attached to the bottom jaw, may increase the load gradually. Thus, the constant rate of flow gives the constant rate of loading.

The function of this applied force is to extend the specimen until it eventually breaks down. Thus, loading causes the extension.

In CRL Method;

- The purpose of applied force is to extend the specimen till there is a breakdown.

- Elongation is caused because of loading.

- This method consists of a container and flow of water which will lead to load increment.

Read: Fabric Strip Test

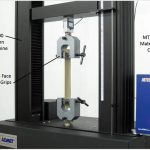

What is CRE or Constant Rate of Elongation?

A specimen is gripped between two jaws; the top jaw which is fixed and the bottom jaw which is moveable in the downward direction at a constant velocity by means of a screw mechanism.

Initially, the tension on the specimen is zero. But, when the bottom jaw moves downwards at a constant rate, the specimen is extended and an increasing tension is developed until the specimen finally breaks down. In this case, the extension causes loading.

In CRE Method:

- The loading is caused as a result of elongation.

- This method is usually a screw mechanism.

- Screws are extended and are used for increasing the tension till there is a breakdown.

Difference between CRE and CRL