Grab Test of Fabric is a tensile strength measuring method that is used to determine the effective breaking strength and elongation of woven, non-woven, and felted fabrics using the principle of a constant rate of extension.

Grab Test of Fabric

This test method is not recommended for glass fabrics, knitted fabrics, and other textile fabrics having more than 11% elongation.

There are two types of test methods to identify the grab strength. They are

- Grab test

- Modified grab test

These two testing methods are alike, but smaller changes are required in sample preparation.

Sampling:

- Sample size: 100x1500mm

- Jaw width – 25mm

- Gauge length- 75mm

Test procedure:

- The sample is clamped between the jaws.

- Set the parameter for the corresponding test in the instrument.

- Speed is adjusted so then the sample is broken in 20±3 seconds.

- Repeat the test for all other warp and weft way specimens. Find the average and the results are expressed separately for warp and weft ways.

Test Results:

- Mean breaking force.

- Mean elongation at break.

Importance of Grab Test

The most common tensile test used in the textile industry is called the grab test. The grab test method is a modification of a standard tensile test for use with woven and nonwoven textile fabrics that measures ultimate strength and elongation.

The grab test eliminates edge effects by clamping the center of the sample width, away from the sample ends, and using jaws smaller than the sample width.

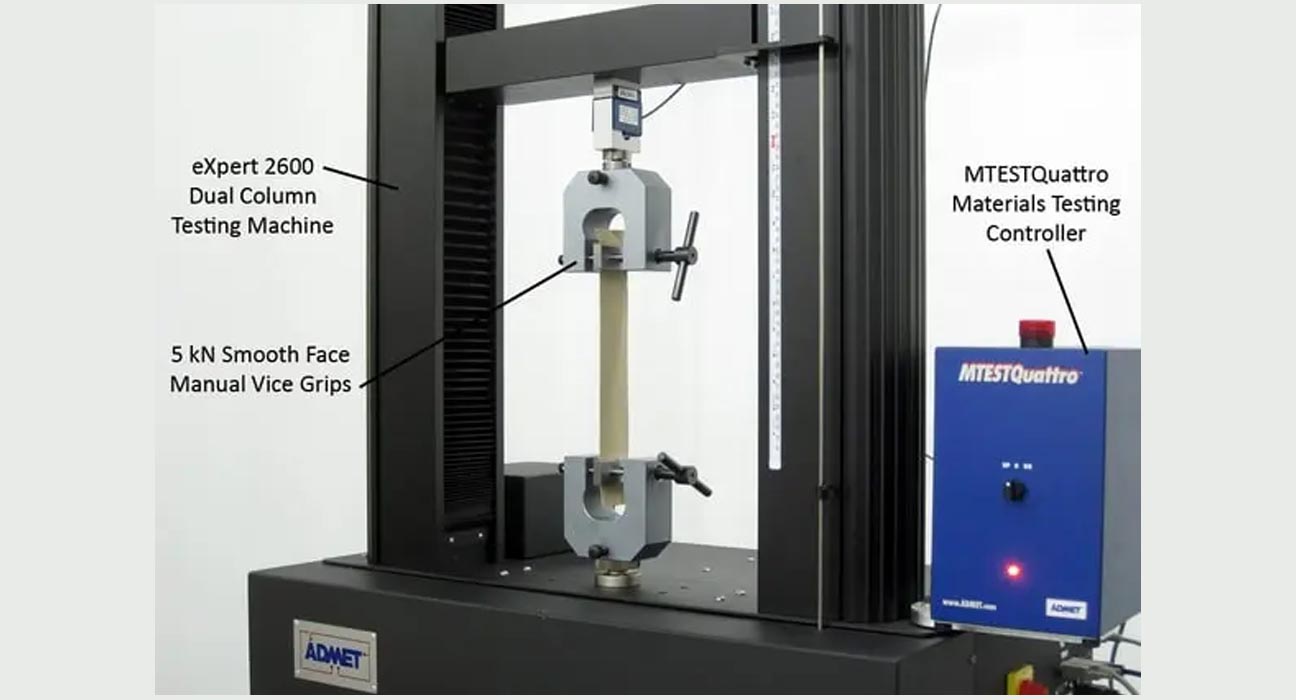

As with all textile tests, alignment of the grip surfaces with the plane of the fabric sample is crucial for achieving accurate results.

However, the orientation of the fabric in the sample is only significant if the material exhibits anisotropic material properties, which would give different strength values for off-axis loading.