Tearing strength is the resistance of the fabric against tearing or force required to propagate the tear once it is initiated. Generally, the resistance offered by a textile material when it is subjected to sudden force is generally termed tearing strength.

The tear strength is required in high-performance applications as well as in conventional textiles, that is, in industrial applications, bulletproof jackets, tents, worker jeans, sacks, aesthetic apparel, and many more applications.

Tearing Strength of Fabric

Types of tearing tests:

- Tongue Test

- Trapezoid

- Wing Rip Tear Test

Tongue method:

Cut it into two pieces along the length of the strip. Apply tensile load in the two clamps of the machine respectively. The yarn in the longitudinal direction experiences tension; the lateral yarn slides.

The tension of the sliding yarn and the elongation increase dramatically and will form a stressed triangle. The first yarn of the bottom incision of the triangle withstands the greatest force. When it tears, it will have the highest tear value.

The yarn breaks one by one until the fabric is torn. Factors affecting the triangle will also affect the fabric’s tearing strength.

So, that is why the strength of tongue tears does not only reflect the tenacity of the fabric, it can also evaluate the effect of the dyeing and finishing process and other factors caused by the friction effect of tear on the impact.

Trapezoidal method:

Draw two diagonal lines at the ends of the strip to form an isosceles triangle in the middle and then cut at the bottom. Try to clamp and follow the two diagonal lines and add tensile loading.

The first yarn that is close to the incision will bear more external force, while the other yarns will endure less force. When the first yarn experiences a crack, it will split.

Then the line below will become the first yarn. It will endure strong tension until tears apart. At last, the maximum force in the process is the tearing strength of the fabric.

It is directly related to the tearing force and is used to evaluate the tenacity of the fabric.

The comparability and stability of the results are good, easy to measure, and can be carried out in normal machines with general strength.

Wing Rip Tear Test:

The Wing rip tear test overcomes some problems which are found with the single rip test as it is capable of testing most types of fabrics without causing a transfer of tear.

During the test the point of tearing remains substantially in line with the center of the grip.

Importance of tear strength test on fabrics:

The tear strength is the resistance of fabric against tearing. The tear strength is vital for textiles, bulletproof jackets, worker jeans, tents, apparel, sacks, and industrial applications.

If the tear strength is high, means punctures in the fabrics do not propagate easily. The tear strength is vital in industrial textiles as heavy-duty work is performed.

Factors affecting the tear strength are as follows:

- The GSM of the fabric indicates the tear strength. High GSM means more tearing strength.

- The strength of the yarn has a direct relation to the tearing strength of the fabric. More yarn strength means more tear strength.

- Weave designs mean the plain weave could have the lowest tear strength. Similarly, the spun yarn has low tear strength as compared to filament yarn.

- The knitted fabric is less strong as compared to woven fabric.

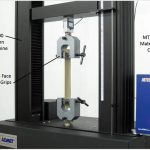

The tearing strength tester is an appropriate tool to measure the tear resistance of various materials including textiles and fabric

Measurement of fabric tearing strength:

Elmendorf tear tester:

Sample Preparation:

- First, we take a specimen of 100 ×75.

- The template is placed on the specimen and cut according to the template, which is given below.

- A slit is created at the middle point of the specimen, which range is 20 mm.

- In the test, the Elmendorf continuously tore the fabric from the end of the slit to the opposite edge distance of 43mm.

- The pendulum lever principle is used here.

Working Procedure:

- The apparatus consists of a sector-shaped pendulum carrying a moving sample clamp & a fixed clamp on the frame.

- When the pendulum is the raised to starting position, the specimen is transferred between the two clamps.

- The tear is started by a slit cut in the specimen between the clamps.

- The pendulum is then released & the specimen is torn as the moving clamp, moves away from the fixed clamp.

- The pointer is attached to the pendulum and is graduated to read the tearing force direct