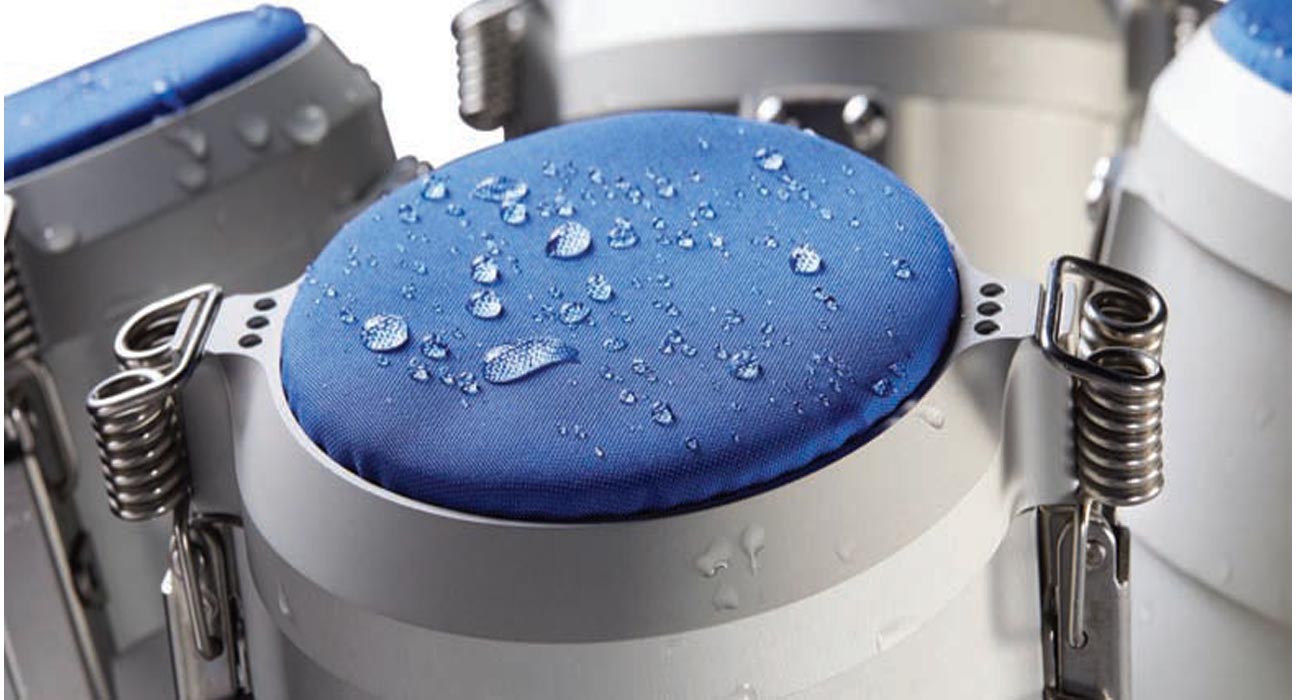

water repellency test using Spray Rating Tester. The tendency of any material to resist wetting is called its water repellency. Water repellency of a fabric depends on several factors including the nature of the fibers, yarn structure, fabric porosity, finish applied, and water impact force. In this test, water is sprayed on the stretched fabric sample from 150 ±2 mm height under controlled conditions. A wetted pattern is produced whose size is dependent on the water repellency of the specimen. The wetted sample is compared to the standard spray ratings to evaluate its water repellency of it.

Objectives:

- To measure the water repellency of a given fabric.

Water Repellency Test of Fabric using Spray Rating Tester

Theory:

Water repellent is a state characterized by the non-spreading of water globules on textile material. Water repellency is a step up from water resistance, which means water cannot easily penetrate the material. This term is not normally applied to a water-repellent finish impervious to air. This is generally referred to as waterproof. It is generally done by treating the fabric with fat, wax, rubber, etc.

This addition may be in form of physical film or coating or physical combination. The feature of waterproof fabric is the low degree of air permeability.

A spray tester is an instrument that measures the water repellency of a fabric. In this test a small amount of shower is produced by pouring water through a spray nozzle. The water falls onto the specimen which is mounted over a 6 in. diameter embroidery hoop and fixed at an angle of 45 degrees.

To carry out the test, 250 ml of water is poured steadily into the funnel. The American Association of Textile Chemists and Colorists recommends the use of a chart of photographs against which the actual fabric appearance is compared.

The ratings are as follows:

Rating Description

- 100 No sticking or wetting of the upper surface.

- 90 Slight random sticking or wetting of the upper surface.

- 80 Wetting of upper surface at spray points.

- 70 Partial wetting of whole of the upper surface.

- 50 Complete wetting of whole of the upper surface.

- 0 Complete wetting of whole of upper and lower surfaces.

Water Repellency Test of Fabric using Spray Rating Tester

Apparatus:

- Spray tester

- Water

- Fabric

Sample: 100% cotton, polyester, umbrella, parachute cloth.

Atmosphere:

- Temperature 25oC and relative humidity – 67%

- Standard atmosphere: temperature – 20oC and relative humidity – 65%.

Working principle of water repellency test:

- The sample fabric is mounted on the embroidery hoop and fixed on the instrument at 45o.

- Now the beaker is filled with 250 ml of water and poured into the funnel.

- The water is showered through a spray nozzle on the fabric.

- After spraying has finished the sample holder is removed and the surplus water removed by tapping the frame 6 times against a solid object, with the face of the sample facing the solid object.

- The water repellency is assessed from the spray rating chart.

- 5 tests should be made and the nearest rating assigned to each since no interpolation is allowed,

- The mean of the 5 ratings is taken as the result.

Experimental Data:

| S/n | Type of fabric | Spray rating |

| 1 | 100% cotton | 0 |

| 2 | Polyester | 0 |

| 3 | Umbrella | 70 |

| 4 | Parachute | 100 |

Table: Ratings found for different fabrics.

Results:

- The water repellency of 100% cotton fabric is 0.

- Water repellency of polyester fabric is 0.

- The water repellency of umbrella fabric is 70.

- Water repellency of parachute fabric is 100.

Remark:

According to the type of fabric water repellency varies from 0-100. From the experiment, we can understand this. It is mainly selected depending on the end use of fabrics.