Perspiration Fastness / Colorfastness to perspiration (acid or alkaline) refers to the ability not to fade and not to stain when the dyed fabric is perspired, and it is one of the main colors fastness testing items of textiles.

Perspiration fastness refers to the ability not to fade and not to stain when the dyed fabric is perspired. People’s sweat consists of complicated compositions, and its main composition is salt. Sweat is divided into acidity and basicity due to differences in people.

Objectives:

1) To determine colorfastness against perspiration.

2)To determine staining fastness

3) Selection of proper raw materials.

Atmospheric Condition: (Temp: 25+/-2 deg cent; R.H: 65+_2%)

Perspiration Fastness

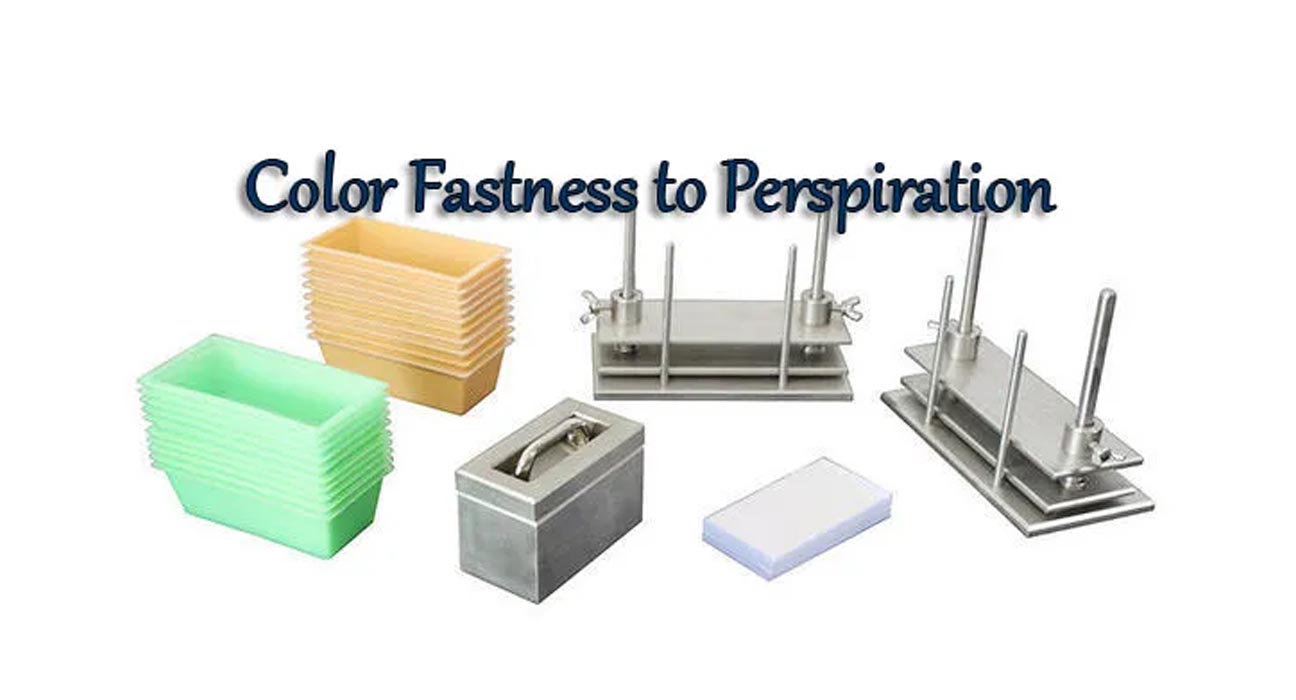

Apparatus:

- Persperometre

- Oven

- Dryer

- Electronic Balance

- pH meter

- sewing tools

- Templates

- Grayscale (Color change & Staining)

Sample Preparation: 10cm X 4cm (Both test sample & multifibre fabric)

Testing Methods: ISO 105 E04

Colorfastness to perspiration

Chemicals:

- L-Histidine monohydrochloride monohydrate

- NaCl

- Sodium dihydrogen phosphate

- Disodium Hydrogen phosphate

- NaOH

- Distilled Water

Recipe:

For Acidic Solution:

- 1:50 (M:L)

- L-Histidine monohydrochloride mono hydrate= 0.5 g/l

- Sodium Chloride= 5 g/l

- Sodium dihydrogen phosphate= 2.2 g/l

- PH=5.5 (to adjust pH using NaOH )

For Alkaline Solution:

- 1:50 (M:L)

- L-Histidine monohydrochloride mono hydrate= 0.5 g/l

- Sodium Chloride= 5 g/l

- Disodium Hydrogen phosphate= 2.5 g/l

- pH=8 (to adjust pH by using NaOH)

Color Fastness to Perspiration

Working procedure:

- To prepare two combined samples as prescribed requests, and weigh; take acid liquid and alkaline liquid at bath rate at 1:50.

- To put two combined samples into acid liquid and alkaline liquid respectively, soak them completely, then place them at room temperature for 30min.

- Take the combined sample out, and use two glass rods to remove excess liquid from it; then place it on the sample board, use the other sample board to scrape excess liquid, and place in between two sample boards, adding the pressure of 12.5kPa and maintain. Using the same method to place another combined sample, but the apparatus of acid liquid and alkaline liquid test should be separate used.

- Place the apparatus with acid and alkaline samples in a woven dryer at 37℃±2℃ for 4 hours.

- Take apart the suture of the combined sample but keep one short edge, unfold it, and drape and dry it in the air with no more than 60℃.

- Use gray cards to evaluate discoloration of the original sample and staining of adjacent cloth.