In this blog post; we will learn about different types of singeing machines. Singeing is a process, where loose hairy fibers are protruded from the surface of the cloth, fabric, and the yarn is removed by burning.

Types of Singeing Machine:

There are three different types of singeing machines:

- Plate singeing machine

- Rotary-cylinder singeing machine

- Gas singeing machine

3 Types of Singeing Machine

1. Hot Plate singeing machine:

Advantages:

- A hot plate singeing machine is suitable for the backfilling finishing process as the fiber ends in the interstices are not removed.

Disadvantages:

- Fiber ends in the interstices of warp and weft are not singed.

- Produces an undesirable fabric luster due to the frictional contact with the hot plate.

- Causes uneven singeing due to difficulty in maintaining uniform plate temperature.

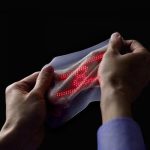

2. Roller singeing Machine:

Advantages:

- The roller singeing machine is suitable for the backfilling finishing process as the fiber ends in the interstices are not removed.

- The uneven singeing takes place to a lesser extent in roller singeing.

Disadvantages:

- Fiber ends in the interstices of warp and weft are not singed.

- Produces an undesirable fabric luster due to the frictional contact with the hot plate.

- Causes uneven singeing due to difficulty in maintaining uniform plate temperature.

3 Types of Singeing Machine

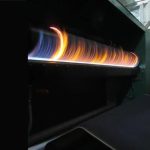

3. Gas-singeing machine:

Advantages:

- Both sides of the cloth are sung simultaneously.

- Uniform singeing of the cloth is obtained.

- There is no question of unwanted cloth sheen as there is no contact with any metal surface as in the case of the other singeing machines such as the roller and hot plate singeing machine.

- Fibers in the interstices between the warp and weft threads are also burned effectively.

- This is not entirely possible in the case of other single machines.

- Different varieties of fabric can be singed.

Disadvantages:

- The major disadvantage of gas-singeing is obviously that there is a great risk of fire if proper care is not taken on this count However, any risk of fire can be avoided completely if,

- The flame is adjusted to be at its optimum size.

- Careful monitoring of the singeing process is carried out.

- The necessary fire-fighting equipment is available close at hand.

- The operators at the machine are properly trained to run the singeing machine and to use the fire-fighting equipment in an emergency.

3 Types of Singeing Machine

Service and Maintenance of Singeing Machine:

- Ensure the feed fabric before brushing is always bone dry.

- Clean pre-brush bottom SS ducts every day to maintain constant efficiency of brushing.

- In the Cyclone Dust Collector, change the plastic collector bag once it is filled up to 80% of its capacity.

- Clean burner slit with cleaning gauge before beginning the singeing process every day with the machine in cleaning mode.

- Ensure the ramp bodies mounted on the burner should be aligned properly (straight). There should not be any gap between two adjacent ramp bodies.

- Ensure while aligning ramp bodies, the edges should be properly matched.

- When the machine is in cleaning mode, make sure the air pressure should be 20 bar.

- Do not clean the ramp bodies with compressed air.

- Always feed dry compressed air to the machine for the proper functioning of the pneumatic system for the burner.

- Maintain cooling water pressure

- Maintain gas pressure at 1 bar (before regulator cum shut off valve).

- Always feed dry LPG or CNG to the machine to avoid fluctuation.

- Always feed ambient temperature (30-35 degree) water to the water-cooled guide rollers to avoid sticking fluff to the roller.

- The pre washer should be thoroughly cleaned every day.

- Ensure proper cleaning of the indirect heating coil in the desizing tank to avoid uneven dyeing.

- The bottom rollers in desizing tank should be thoroughly cleaned every day to increase the life of spherical carbon-bearing.

- Always use oil cups suggested by Osthoff on squeezer rollers to increase the life of bearings.

Types of Singeing Machine: References:

- https://en.wikipedia.

- https://textilelearner.blogspot

- https://textilesscholars.blogspot

- https://textilecourse.blogspot.

You May Read:

FAQ

What is Singening in Textile ?

Singeing is a process, where loose hairy fibers are protruded from the surface of the cloth, fabric, and the yarn is removed by burning.

What are the three types of Singening Machine?

There are three different types of singeing machine:

- Plate singeing machine

- Rotary-cylinder singeing machine

- Gas singeing machine