Experiment Name: Study on tappet shedding mechanism

Introduction:

Tappets are generally used for heald shedding. Tappet is a type of cam to which a rotary motion is given for the purpose of producing reciprocating motion in rods and levers by sliding contact. When the rod is to receive a series of lifts, with intervals of rest thus forms a shed called a tappet.

Objectives:

- Learn about the shedding mechanism of tappet loom

- Learn about different parts related to this mechanism.

- Know the construction of tappet shedding.

- Know the working procedure of the tappet shedding mechanism.

Description:

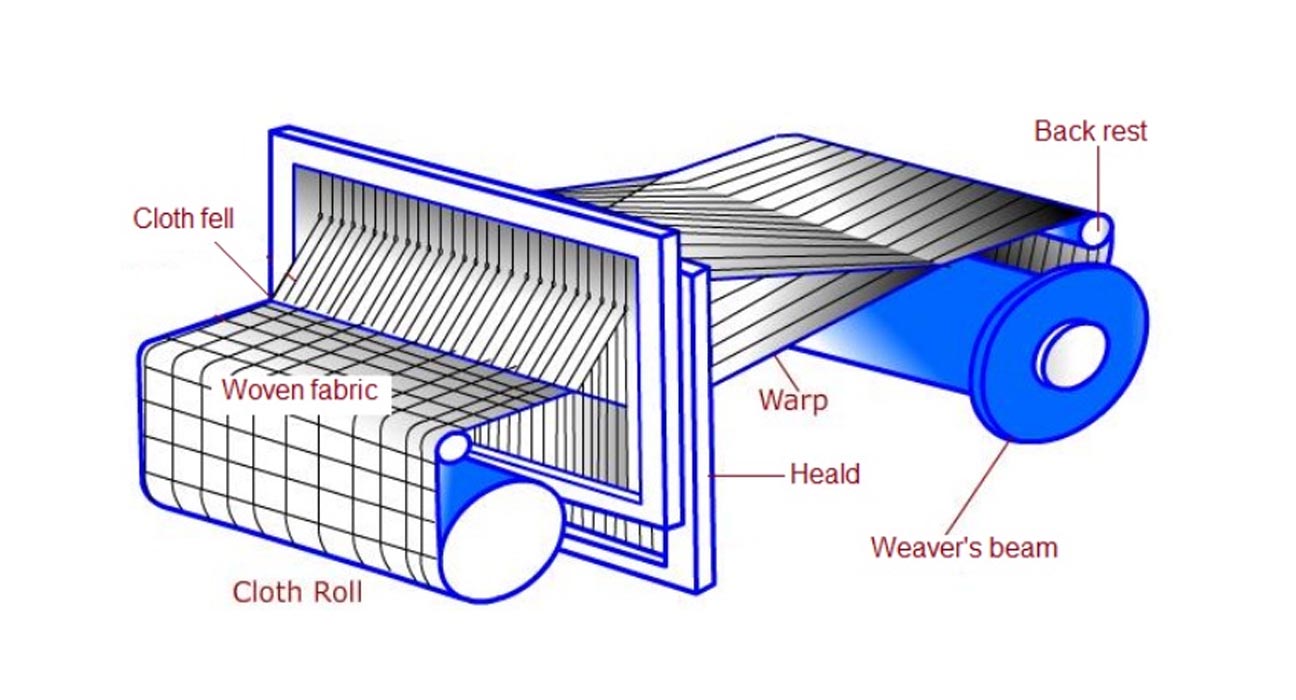

A tappet is a shedding tool placed on the peak of a loom in order to produce a pattern by using a limited number of heads. The tappet shedding is the combination of tappets and cams motion that the reason of shafts is lifted up to form the shed.

Types of Tappet Shedding Mechanism

There are two types of tappet shedding mechanisms.

-

Negative shedding tappet

In this mechanism, lifting is done mechanically, and lowering is and lowering is done by spring. That means Negative tappet needs an extra arrangement of pulley, bowl, spring and dead weight to reverse the direction of healds. This belt pulley either raise or lower the head.

Example: Shuttle loom.

-

Positive shedding tappet

In this mechanism, both lifting and lowering motion are done mechanically. Which means this mechanism provides both upward and downward movement of heald without the help of additional mechanism.

Example: Rapier loom.

Main parts of Tappet Shedding Mechanism:

- Motor.

- Motor pulley.

- M/C pulley.

- Crankshaft.

- Crankshaft gear.

- Bottom shaft gear.

- Bottom shaft.

- Tappet.

- Connecting rod.

- Heald shaft.

- Top arm.

Construction of negative shedding mechanism:

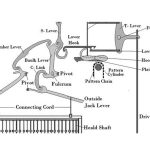

The figure shows a negative tappet shedding mechanism. A pair of tappets A and B are fixed to the bottom shaft C at 180 degrees to each other. Two treadle levers D and E are connected to the loom back-rail by a bracket or fulcrum F.

The bracket acts as a fulcrum for the levers. The two treadles have teeth to carry the lamb rods G and H respectively. Two heald shafts J and K are connected to the lamb rods. A top reversing roller shaft Q carries two rollers of different diameters. The roller of small diameter N is connected to a leather strap L to which the front heald shaft J is connected. The roller P of large diameter is connected to a leather strap M to which the back heald shaft K is connected. The tappets A and B touch the anti-friction bowls or followers R and S respectively, which are fixed to the treadle levers.

The heald shafts have heald eyes T and U through which the war p threads pass X is the war p sheet and Y is the cloth. The odd ends are passed through one heald shaft while the even ends are passed through the other heald shaft.

Working Procedure of negative tappet shedding:

When the bottom shaft is rotated in the clockwise direction as shown in the figure, the tappets are also rotated. The tappet will depress the anti-friction bowl and the treadle. Being fulcrumed at one end, the front portion of the treadle moves down. This action is transferred to the lamb rod, the heald shaft and the leather strap. So, one heald shaft is lowered and the threads connected to this heald shaft are lowered and form the bottom layer of the shed.

The leather straps attached to the reversing rollers are connected in opposite directions, i.e. when leather strap is pulled down, it is unwound from its roller. The shaft therefore rotates in the clockwise direction and the other leather strap is wound on to its roller. The heald shaft is raised and therefore the lamb rod and treadle lever are also raised. The threads connected to the heald shaft are also raised and form the top layer of the shed.

For the next shed, the other tappet works with the other set of bowl, treadle, lamb rod, heald shaft, strap and roller and the other heald shaft is lowered. The first heald shaft is raised by the top reversing rollers, and the positions of the healds shafts are thus interchanged. Thus, for one rotation of the bottom shaft, two sheds are formed.

In this type of tappet shedding therefore, one tappet depresses the concerned treadle and the corresponding heald shaft is lowered. But the other heald shaft is raised by means of the top reversing rollers. So, this type of shedding mechanism is known as “negative tappet shedding mechanism”

Construction of Positive shedding mechanism:

The tappet shaft carries another tappet which has a groove or track in which a bowl is placed. The bowl is connected in turn to a tappet lever with link rods, links J, and a heald shaft. Each tappet is separately connected to a heald shaft through link rods and a tappet lever. There are two fulcrums for the tappet lever and links.

Working Procedure of Positive Tappet Shedding:

When the tappet is rotated, the bowl is also rotated. According to the shape of the groove, the bowl is moved up or down or is still. If the bowl is moved up, the tappet lever moves to the right through the links and the heald shaft is lowered. If the bowl is moved down, the tappet lever moves to the left and the heald shaft is raised. Since the heald shaft is raised and lowered by means of the mechanism, this tappet shedding is known as positive tappet shedding mechanism. When the bowl stands still, the heald shaft is in the dwell stage.

A positive shedding tappet, and the one most generally employed, is known as the Wood croft tappet. This style of tappet is self-contained, and is now made in three different forms, according to the class of fabric for which it is to be adopted. The treadles are fulcrumed on the shaft and are provided at with a knuckle, on which the antifriction pulley is pivoted. The pulleys are specially tempered or made of steel in order to better resist the friction to which they are subjected. The movement of this pulley and at the same time the treadle is determined by the shape and the arrangement of the section plates 1 to 12. In this type of tappet only two different section plates are used.

That shown at it is employed to raise the treadle; that is to depress the treadle. The pulley is actuated by the projecting rims of metal cast on the side of the plates with which it is in constant contact. The healds are connected to jack levers placed above and below the healds; the levers extend outside the loom frame, and in turn are attached to the end of the treadle by means of the connector. When the treadle is forced upwards by means of a section plate, the heald shaft is drawn down, and vice versa, with the section plate.

These tappets are made to work with from 8 to 12 treadles, and can be constructed for weaves containing up to 24 picks to the round. A tappet contains 12 sections or picks in one repeat. The tappet shaft is supported in open bearings in the framework, and secured to this shaft the tappet wheel, containing a number of teeth (in this 180) which is a multiple of the weaves for which the tappet may be required. The wheel is also fitted width a number of standard bolt holes, in order to accommodate section plates of different sizes, such are required for weaves containing a varying number of picks to the round.

Conclusion:

Student will be able to understand the tappet shedding mechanism which is important for driving the loom. It is also important for fabric design.