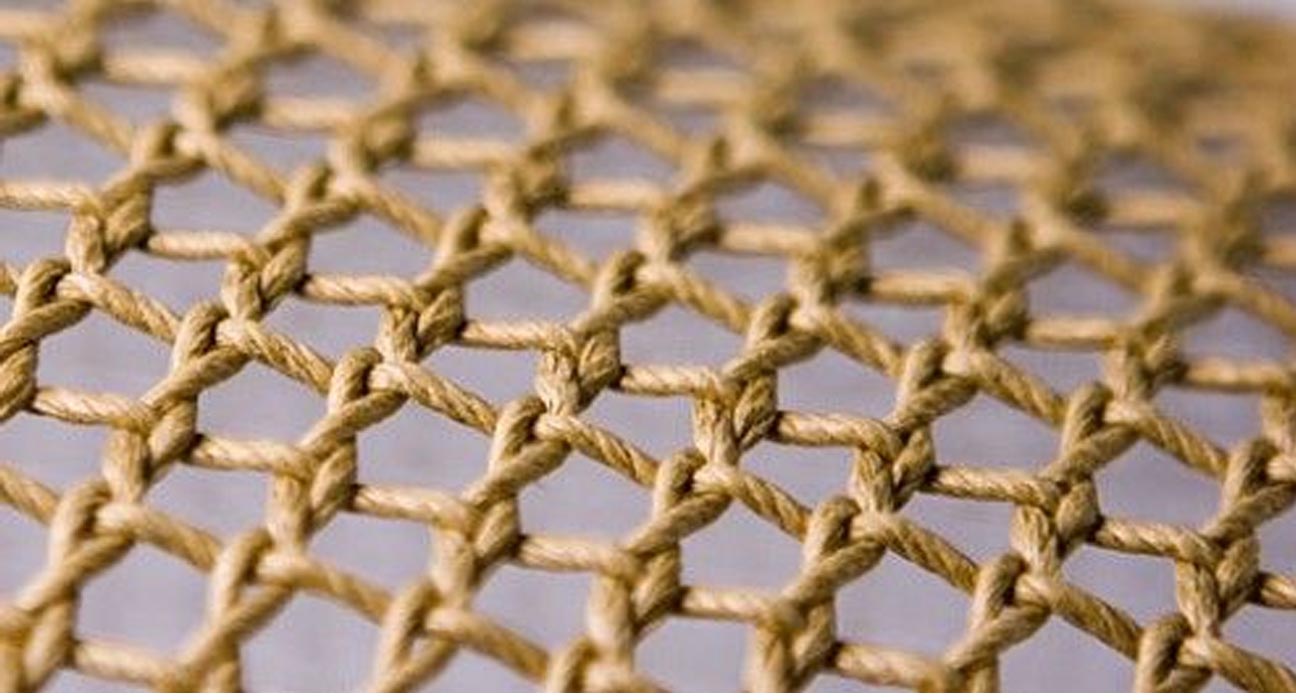

Leno Weave Fabric is produced by Leno Weave also known as gauze weave or cross weave. A leno weave is created by twisting two yarns together for the warp yarns.

These yarns create a helix-like structure. The weft yarns are interwoven through the holes created in the twisted warp yarns.

This is done using a special loom attachment called a ‘Doup’ and this means that the interwoven warp and weft yarns are locked in place. This technique creates a staple fabric which is very unusual in an open weave fabric.

Some Examples of fabrics made from leno weave are Gauze fabric, Net, and Tulle fabric.

Leno Weave Fabric Properties

- Sheer

- Durable

- Staple

- Open Weave

- Gauze-like

- Light and air can pass through

- Breathable

- Flexible

- Versatile

- Available in various colors

- No thread slippage

What are the uses of Leno Fabric?

Leno weave fabric, which allows light and air to pass through freely, is used in any area where a sheer, open weave fabric that will not bruise (where the threads shift away from their original positions, disturbing the uniformity of the weave) is required.

If a simple in-and-out flat weave were woven very loosely to achieve a sheer fabric, the threads would tend towards this bruising. Leno weaves are often used for window treatments and for sheer layers for fine clothing.

When made with glass fiber or other strong yarns or when permeated with a strengthening compound, it can be used as an engineering material in construction.

Due to the openness of the fabric, if a solid covering is required in a construction context, it is often used in conjunction with other weave styles.

End Products leno woven fabric include:

- Produce bags – onions, potatoes, cabbage

- Shellfish bags – oysters, mussels, and clams

- Firewood bags

- Curtains and drapery

- Mosquito netting

- Clothing

If you have any queries, leave a comment below.