Rubbing fastness / Color Fastness to Rubbing determines the ability to sustain the original color of dyed fabrics and the degree of color that is transferred to the adjacent white fabric during rubbing.

Dry rubbing color fastness refers to the situation of fading and staining of dyed fabric when rubbed with a standard white cloth.

Wet rubbing color fastness refers to the situation of fading and staining of dyed fabric when rubbed with a standard white cloth that contains water 95% to 105%.

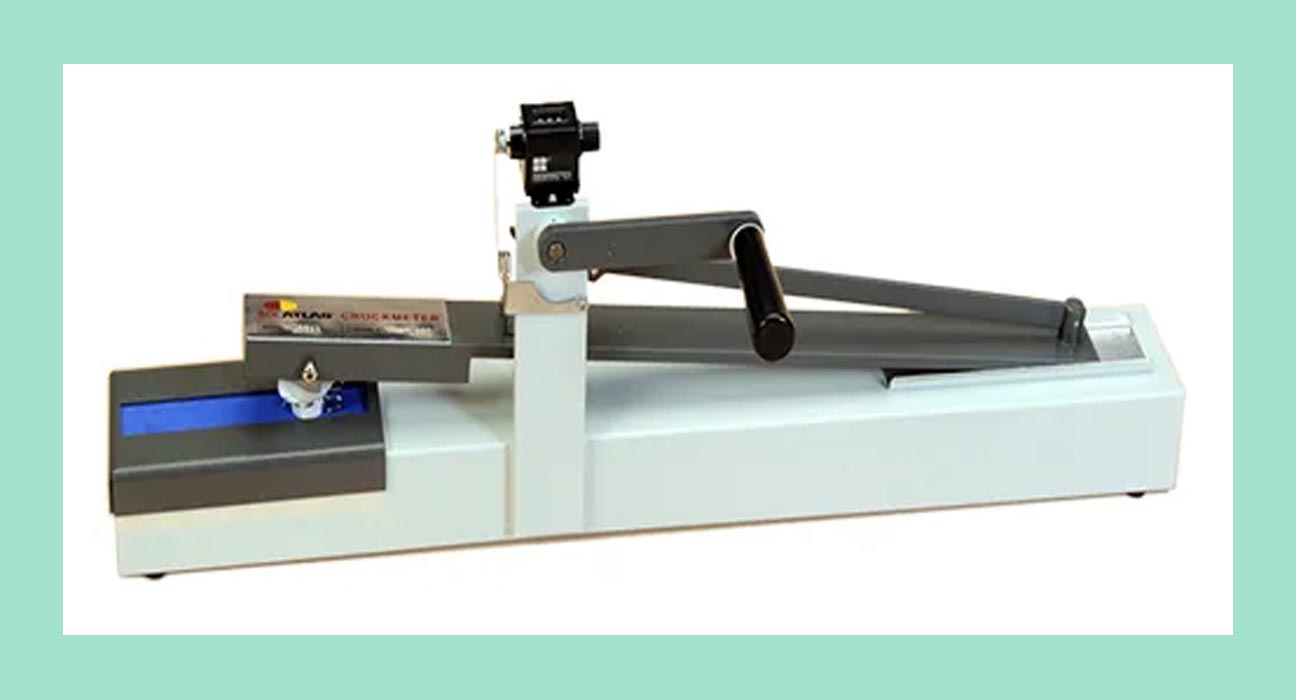

Crock meter is used for performing the test. The evaluation of rubbing color fastness is done by using Gray Scale where grade 5 is the best and grade 1 is the worst.

Color Fastness to Rubbing

Sample Preparation

- Two specimens are used, one each for the dry and the wet tests.

- Additional specimens may be used to increase the precision of the average.

- samples should be not less than 50mm*200mm

- If the sample is multicolor, choose sample’s position should be carefully chosen and let every color rubbing.

Rubbing Fastness Working Procedure

- The sample is fixed on the bottom floor of the tester by a clamping device, and its length direction is in accordance with the movement direction of the tester.

- A dry rubbing cloth is fixed on the friction head/rubbing finger of the tester.

- Pressing Start Switch, 10 times reciprocating rub is done, and then take the dry rubbing cloth off. Reciprocating movement is 100mm, and vertical pressure is 9N.

- Taking another rubbing cloth is soaked in cool water, to make moisture content 95% to 105%.

- The first three steps are done repeatedly. When rubbing is finished, dry it at room temperature.

- Use gray cards to evaluate staining to measure the staining fastness of the above dry and wet rubbing cloths.