Carbon fibers have several advantages including high stiffness, high tensile strength, low weight, high chemical resistance, high temperature tolerance, and low thermal expansion. (Amazing Facts of Carbon Fiber)

These properties have made carbon fiber very popular in aerospace, civil engineering, military, and motorsports, along with other competition sports.

Amazing Facts of Carbon Fiber

1. Carbon Fiber is not a new idea. Carbon fiber was originally invented in 1958 near Cleveland, Ohio.

2. Carbon Fiber is made from two different materials. You may have heard carbon fiber referred to as a “composite.” This is because carbon fiber is made from two different materials, that when combined, create a single material with the benefits of both constituents.

3. This Fiber is used for cars and planes.

4. Most Raw Carbon Fiber is formed in Asia.

5. The term ‘carbon fiber’ can mean many different things. A key carbon fiber fact is that it comes in many different forms. Carbon fiber is produced in sheets, clumps of raw fibers, in short, fiber lengths, or in long fiber lengths.

6. Carbon fiber is something of a dream material One of the most fun facts about carbon fiber relates to how easy it is to work with. It is firmer and stronger than many other materials, and yet also lighter. This makes it a dream material for engineers and manufacturers.

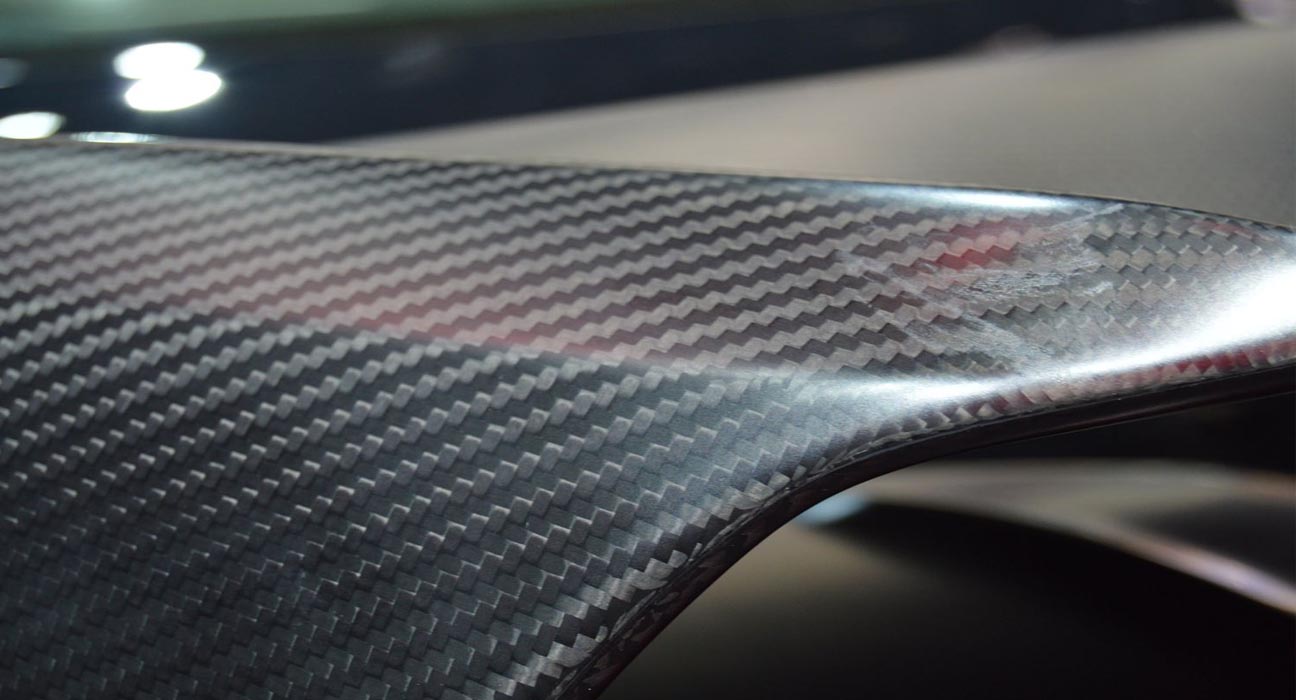

7. Carbon fiber weaves are mainly cosmetic. The carbon fiber weave that so many of us enjoy does serve a purpose and provides limited protection against scratches and other superficial damage. However, it is mainly used for a cosmetic effect…and a very nice one at that.

Amazing Facts of Carbon Fiber

8. Manufacturing is a hands-on process. Many of us might consider carbon fiber to be a futuristic material, processed entirely by machines and on robotic production lines. However, a great deal of hands-on work goes into production. Of course, there are automated phases in the process, but a serious amount of human labor is also involved, which will make you appreciate that gorgeous shoulder bag all the more.

9. Carbon fiber consists of extremely thin fibers ranging from 0.005 to 0.010 mm in diameter. First thousands of carbon fibers are twisted together to form yarn. This yarn is then weaved into carbon fiber cloth.

10. Carbon fiber cloth has many different weave patterns and when combined with a resin it can be molded to form a high strength-to-weight ratio composite material.

Conclusion

The original concept was used in insulation, filtration, and lighting applications. Years later, a company called Union Carbide developed a carbonized cloth that they presented to the U.S. Air Force as a replacement for fiberglass. Although the mechanical properties of these early materials fell short, Union Carbide realized the material’s potential and later perfected the process that creates carbon fiber as we know it today

Author: Niloy Kundu Bejoy