INTRODUCTION

Textile fibre is the material obtained from a natural or synthetic source. Study of Properties and uses of Natural Fibre is important because properties of the fibre are mainly concerned with the internal and surface structure of fibre and both control the behaviour of fibre in yarn and fabric.

WOOL FIBRE

Physical properties of wool fibre:

1. Length- length of wool fibre may vary from 3.6 to 35 cm

2. Fineness- fineness range- 10-70 microns

- Merino wool- 10-30 micron

- Carpet wool- 20- 70 micro

3. Cross-section- a cross-section of wool fibre it may vary from circular to elliptical.

4. Crimp-

- Fine wool – 14-22 crimps per inch

- Medium wool – 8-14 crimps per inch

- Coarse wool – up to 8 crimps per inch

5. Strength- Avg strength of the wool fibre is 1 to 1.7 gram per denier

6. Colour- colour may yellowish but may be brown to black

7. Lustre –

- Coarse fibre – high lustre

- Fine fibre – less lustre

8. Elongation – 25-35%

9. Moisture regain – 15-18 %

10. Specific gravity – 1.3 to 1.32 gm/cc

11. Elasticity – 90-92%

12. L:D – 3000:1

Chemical properties of wool fibre:

- The action of heat – heated in dry air at 100 to 110 covers a long period it loses its moisture and strength. Decompose and turn to yellow colour.

- Effect of water and steam– Exposed to water and steam, with or without tension, wool will change in its shape and affinity to dye.

- Effect of Acid – Acid like Hcl andH2So4 wool is hydrolyzed immediately and salt is formed with an amino compound which dissolves in acid medium.

- Effect of alkali– wool dissolves completely in 5% NaOH (caustic soda ) at boiling. And disintegrated with dilute NaOH.

- Effect of salt – calcium and magnesium salt in hard water causes the yellowish effect on prolonged boiling.

- The action of the oxidizing agent – damage of wool is more or less depending upon temp., conc., and pH.

Applications of wool:

- Blankets

- Clothing

- Upholstery

- Outerwear

- Suits

- Carpets

- Insulation, etc.

COTTON FIBRE

Cotton fibre is the purest source of cellulose and the most significant natural fibre. It is more popular for its variety of use. Cotton fibre is most used fibre for producing various type of fabric all over the world. Cotton fabric is comfortable to wear because of its unique fibre property. It has its own physical and chemical property which give better processing I spinning, weaving, knitting, dyeing, printing and finishing.

The physical property of cotton fibre:

- Tensile strength – cotton is moderately strong fibre. The tenacity of cotton fibre is lies between 3-5 gm/denier

- Breaking elongation – 8-10%

- Specific gravity – 1.54 gm/cc

- Moisture regain – the standard is 8.5

- Colour – normally the colour of cotton is creamy white

The chemical property of cotton fibre:

- Effect of acid- Concentrated acid such as sulphuric acid and hydrochloric acid damages the fibre. But weak acid not damages the fibre.

- Effect of alkali – Alkali does not damage the fibre

- Effect of organic solvent – Cotton dissolve in concentrated 70% H2SO4

Application of cotton:

- Shirts

- Blouses

- Childrenswear

- Swimwear

- Suits

- Jacket

- Skirts

- Pants

- Sweaters

- Hosiery

- Table cloths

- Tablemats

- Napkin

JUTE FIBRE

Jute is a natural fibre popularly known as the golden fibre. It is one of the cheapest and the strongest of all-natural fibres and considered as fibre of the future. Jute occupies a second place next to cotton in the world’s production of natural fibre.

Physical properties of jute fibre:

- Fibre length – 50 to 300 mm

- Fibre diameter – 0.035 to 0.14 mm

- Specific gravity – 1.48 gm/cc

- Fibre denier – 6 to 50

- Tenacity – 2.7 to 5.3 gm/tex

- Breaking elongation – 0.8 to 1.8 %

- Moisture regain – 13 %

- L:D – 110 to 140

- Unit cell length of 0.8 to 6 mm

- Traverse swelling in water – 20 to 22 %

Chemical properties of jute fibre:

1. Chemical composition

- Cellulose – 58-63%

- Hemicellulose – 20- 22%

- Lignin – 12 – 14.5 %

- Wax and fats – 0.4 -0.8%

- Pectin – 0.2 -0.5 %

- Protein – 0.8 – 2.5 5

- Mineral matter – 0.6 -1.2%

2. Prolonged heating causes degradation of jute fibre.

3. The action of heat – strong acid at boiling causes hydro cellulose and lead to a loss in strength. But dilute acid have no effect on jute fibre.

4. The action of alkali- Dilute alkali has no effect of jute fibre, but strong alkali at boil causes loss in strength.

Application jute fibre:

1. Industrial textile

- Tarpaulin

- Jute geotextile

2. Apparel textile

- outerwear

- suits

- hessian cloth

3. Home textile

- floor covering

- carpets

- upholstery

- chair covering

- curtains

Properties and uses of Natural Fibre

Silk Fibre

Physical properties of silk fibre:

2. Diameter – 0.013 to 0.08 mm

3. Denier – 2.3 ( raw state ) and 1 to 1.3 ( Boiled state )

4. Microscopy-

- cross-section – Elliptical

- longitudinal view – Rough surface

5. Moisture regain – 11% at 65 % R.H and 27 c

6. Tensile strength – 3 to 4.5 gram per denier

7. Elongation – 18 to 22 %

8. The electrical property-poor conductor of electricity and accumulation of static charge.

9. Density – 1.33 gm/cc ( Raw state ) and 1.25 gm/cc ( Boiled state )

Chemical properties of silk fibre:

- The action of heat – At 170 c silk is rapidly disintegrated. On burning it liberates and colour similar to burning of hair.

- The action of acid – Lusture of the silk increases as it absorbs the dilute acid. It can be decomposed by strong mineral acid. Conc. acid such as sulphuric acid and hydrochloric acid dissolves the silk.

- The action of Alkali – silk is not sensitive to dilute alkali but strong caustic alkali dissolves the silk.

- Effect of organic solvent – Cleaning solvents and spot removing solvents like carbon tetrachloride, Acetone etc. do not damage the silk.

- Effect of sunlight – sunlight tends to accelerate the decomposition of silk. It increases oxidation and results in fibre degradation.

Biological property of silk:

Silk is resistant to attack by mildew, other bacteria, and fungi. It is decomposed by rot producing conditions

Applications of silk:

➢ Home textile

- Decorative curtains

- Upholstery

- Silk throws and pillows

➢ Apparel textile

- Silk sarees

- Decorative outerwear

➢ Medical textile

- Absorbent pad

- Wound contact layer

FLAX FIBRE

properties of flax fibre:

- Length – Avg. length of flax fibre varies from 90 to 125 cm

- Diameter – Avg. diameter is about 0.02 mm

- Tensile strength – Tenacity varies from 6.5 to 8 gram per denier

- Elongation – Elongation at break is approx. 1.8 % (dry) and 2.2 % (wet)

- Specific gravity – 1.50 gm/cc

- Colour – Brownish, gey, yellowish, light.

- Lustre – Good lustre because of natural wax content.

- Moisture regain – 12% (std)

- Abrasion resistance – Moderate

- Thermal property – excellent conductor of heat

- Resilience – Poor electricity

- Washing property – completely washable.

- Dimensional stability – Good but tends to crease more easily.

Chemical properties of flax fibre:

- The action of Acid – There is no effect of dilute acid on flax fibre if it washed immediately, but concentrated acid damages the flax fibre.

- Effect of alkali – Flax fibre has excellent resistance of alkali. It is not degraded by strong alkali.

- Effect of bleaches – Cool chlorine and hypo chloride bleaches does not affect flax fibre.

- Dyes – It is not suitable for dyes, but it can be dyed by direct or vat dye.

Application of flax:

- Household clothing

- Sheeting

- Lace

- Canvas

- Sewing threads

- Surgical threads

- Table cloth

- Bed linen

- Wallcovering

- Insulations

- Draperies

Properties and uses of Natural Fibre

BANANA FIBRE

Properties of banana fibre:

- Banana fibre is similar to that of bamboo fibre, but its fineness and spin ability is better.

- It is a highly strong fibre

- It has a smaller elongation.

- It has got a shiny appearance depending upon its extraction and spinning process.

- It is lightweight

- It absorbs as well as release the moisture very fast.

- It is biodegradable and it has no adverse effect on the environment. So that it can be classified as eco-friendly fibre.

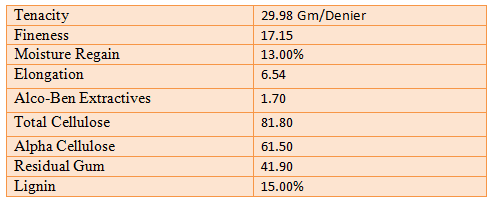

The chemical property of banana fibre:

|

Applications of banana fibre:

- Marine ropes

- Cables

- Mats

- Abrasive backing paper

- Attractive pattern cloth

- Pillows, matrices, cushions

- Cushion cover

- Table cloth

- Bags

- Curtains

BAMBOO FIBRE

BAMBOO FIBRE

‘BAMBOO’ fibre is cellulose fibre extracted from the natural growth of bamboo, is the fifth natural fibre following the cotton, linen, wool and silk. Bamboo is the fastest growing woody plant on this planet. It grows one third-fastest than the fastest-growing tree. Sometimes the growth of bamboo is approximately three feet over the day. Bamboo fibre comes from nature, and completely returns to nature in end, therefore bamboo fibre is praised as ‘Natural, green and eco-friendly new type of textile material of 21st century’. Bamboo is a biodegradable textile material. As natural cellulose fibre, it can be 100% biodegradable in soil by microorganism and sunlight. Its decomposition process doesn’t cause any pollution environment. Bamboo products are further characterized by their good hydrophilic nature, excellent permeability, soft feel, excellent dyeing behaviour and its antibacterial property.

Properties of bamboo fibre:

- Bamboo fibre has good durability, lusture, stability, moderate tenacity and good spinnability.

- It is naturally antibacterial, UV protective, biodegradable, breathable cool, strongly flexible, soft and it has a better shiny appearance.

- Bamboo fibre is further characterized by its good hydrophobic nature, good permeability, soft feel, excellent dyeing behaviour and its antimicrobial property.

- Bamboo fibre absorbs and evaporates moisture quickly.

- It is more breathable, so it gives better comfort to the wearer.

- Bamboo fibre has various micro gaps and micro-holes leading to much better moisture absorption and ventilation.

- Bamboo fibre can be softer than silk fibre when spun into yarn.

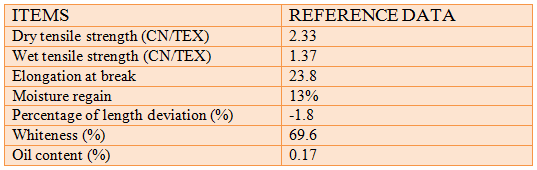

Physical characteristics of bamboo fibre:

|

End-uses or Application of bamboo fibre:

● Apparel textile :

- Sweaters

- Bath suits

- Mats

- Blankets

- Towels

- Underwear

- Socks

● Medical textile :

- Sanitary napkins

- Masks

- Mattress

- Food packaging bags

- Bandage

- Gowns

- Surgical cloth

● Home textile:

- Curtains

- Wallpaper

- Sofa covers

- Table cloth

- Bedsheets

SISAL FIBRE

Properties of sisal fibre:

- Sisal is exceptionally durable and recyclable.

- It is antistatic, does not dust particle and does not absorb moisture or water easily.

- Fine fibre ( from outer leaf skin ) takes dyes easily, offers the largest range of dyed colour.

- It has good sound and impact-absorbing property.

- Its leaves can be treated with natural borax for fire resistance property.

- Sisal fibre is creamy white in colour.

- Avg.fibre length 80 to 120 cm and 0.2 to 0.4 mm in diameter

- Coarse and inflexible.

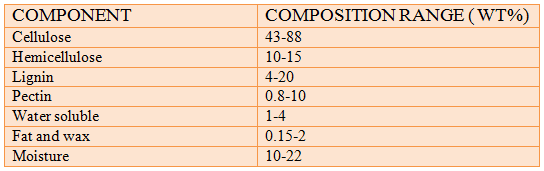

Chemical composition sisal fibre:

|

End-uses (Application) of Sisal fibre:

- Paper industry (lower grade fibre)

- Ropes (medium grade fibre)

- Carpets (higher grade fibre)

- Filters

- Geotextile

- Mattresses

- Handicrafts

- Wire rope cover

- Woven floor covering etc.

Properties and uses of Natural Fibre

PINEAPPLE LEAF FIBRE (PALF)

‘PALF’ is obtained from the leaves of the plant ‘Ananas cosmos’. The plant belongs to Bromeliaceae family. Pine is a Spanish word which means cone-shaped. At present, PALF is widely cultivated for fruit in the tropical and subtropical region of the world. Philippines and Taiwan are the chief producers of the pineapple plant. But it is also available in Brazil, Indonesia, India and west indies. Cultivated land in India is about 87200 hectares given by SITRA. Pineapple natural fibre has excellent mechanical strength, but due to lack of knowledge is still not utilized properly. It can be used in various application like artificial fibre as a sound absorber and thermal insulator. Pineapple leaf fibre (PALF) is one of the abundantly available waste material of Malaysia. PALF can be a new source of raw material for the industries and can be a potential replacement of the expensive and non-renewable synthetic fibre.

Properties of PALF or pineapple leaf fibre:

- Optical microscope – PALF is multi cellulose fibre like other vegetable fibre. Cells in the fibre have an avg. the diameter of about 10 microns and mean length 4.5 mm.

- Electronic microscope – PALF has a scaly cellular structure with vegetable matter intact. In raw fibre, the lumen is present in cross-section, the hollow structure represents that PALF will have high insulation power and high absorbency.

- Physical characteristic – ( Ultimate cells )

- Thermal property – Thermal conductivity of PALF is found to be low at 0.0273 watts/m2/k which suggest that these fibres could be used as good thermal insulators.

The chemical property of PALF:

- Effect of Alkali – When the PALF is treated with 18% NaOH it enhances the breaking elongation and it also results in length shrinkage.

- Effect of H2O2 – Hydrogen peroxide improves its fineness by 5 to 6 %, but reduces tensile strength by 40 to 45 %.

- Dyeing property – PALF has a higher dye absorption tendency as compared to cotton due to its higher moisture regain.

Application of pineapple leaf fibre:

- Barong Tagalog

- Wedding dresses

- Table linen

- Mats

- Bags

- Shoes

- Sports items

- Upholstery

- Reinforced roofing

KAPOK FIBRE

KAPOK fibre is one of the natural cellulose fibre which grown on kapok plant. This fibre is also known as silk cotton because its natural lustre is similar to that of pure silk. kapok is similar to cotton but it can be easily distinguished when it tested under the microscope. short length and smooth surface of fibre cause poor interfiber friction so that it can be easily processed on the modern spinning machine.

Properties of kapok fibre:

- Average linear density – 0.064 tex

- Average diameter – 2.5 micrometre

- Average length – 20 mm

- Fineness – 0.4 – 0.6 denier

- Tenacity – 1.4 to 1.74 gm/den.

- Elongation at break -1.8 to 4.23

- Absorbency – kapok fibre has high lumen percentage, because of this it has excellent oil absorbency and retention capacity.

- Lightweight – kapok fibre is 8 times lighter than cotton by volume

- Effect of acid – kapok fibre shows good resistance to acid and it not affected by acid.

- Effect of alkali – kapok fibre is not affected by alkali, that shows good resistance to alkali.

- Chemical composition

● Cellulose – 64 %

● Lignin -13 %

● Pentose – 23 %

End-uses of kapok fibre-

- Mattress

- Clothing

- Technical textile

- Insulating material

- Medical textile

- Cushions

- Upholstery furniture

- Life jackets

COIR FIBRE

The physical property of coir fibre:

- Avg. length – 6 to 8 inch.

- Density – 1.44 gm/cc

- Tenacity – 10 gm/ tex

- Breaking elongation – 30 %

- Swelling in water – 5 %

- Moisture regain – 10.50%

Chemical composition of coir:

- Lignin – 45.84 %

- Cellulose – 43.44

- Hemi-cellulose -0.25 %

- Pectins -3 %

- Water-soluble – 5.25 %

- Ash – 2.22 %

End-uses of coir fibre:

- Rope

- Doormats

- Mattresses

- Geotextile

- Home decoration pieces

- Toys

- Brushes

Properties and uses of Natural Fibre

Conclusion

Textile fibre is the material obtained from a natural or synthetic source. Fibre which is obtained from a natural source is mainly termed as a natural fibre, as they are originated from a natural source. There are three main sources from that natural fibre can be produced. Cellulose fibre (origin from the plant), protein fibre (origin from the animal) and also mineral fibre. This three kinds of fibre could produce staple yarn (short fibre) in which fibre length is not too long as compared to that of synthetic fibre.

A natural fibre may further be defined as an agglomeration of cells in which diameter is negligible in comparison with length. Although natural fibre material, especially cellulosic type such as cotton, in which number can be used for textile products and other industrial purposes. Apart from economical consideration, the usefulness of fibre for a commercial purpose is determined by properties of fibre like length, strength, pliability, elasticity abrasion resistance, absorbency and various surface property.

Hence the study of fibre property is important. The natural fibre is classified according to its origin. Vegetable or cellulose base, class include fibre such as cotton, flax, and jute. The animal or protein-based fibre include wool, mohair and silk. An important class in mineral class is asbestos. Study of fibre property is important because properties of the fibre are mainly concerned with the internal and surface structure of fibre and both control the behaviour of fibre in yarn and fabric.

REFERENCES:

- Properties of Natural Fibre – Scribd https://www.scribd.com › doc › Properties…

- http://textilefashionstudy.com/physical-chemical-properties-of-jute-identity-of-jute-fiber/

- A Review on Pineapple Leaves Fibre and Its Composites – Hindawi https://www.hindawi.com › journals › ijps

- Silk Fiber | Physical And Chemical Properties Of Silk | Textile Fashion …

- Introduction of Textile Fiber | Classification of Textile Fiber – Textile Learner textilelearner.blogspot.com › 2011/05

- Wool | animal fibre | Britannica.com https://www.britannica.com › topic › w

- Properties of Banana Fiber | Manufacturing Process of Banana Fiber … textilelearner.blogspot.com › 2014/01

- Flax Fiber | Properties of Flax Fiber | History of Flax Fiber | Applications of … textilelearner.blogspot.com › 2011/08 › f…

- Introduction Of Bamboo Fiber – Blogs

- Natural Fibres from Sisal | Wild Fibres natural fibres