Singeing is a part of the pretreatment processes carried out in textile processing, and is usually the first step carried out after weaving.

What is Singeing in Textile?

Singeing is a process, where loose hairy fibers are protruded from the surface of the cloth, fabric, and the yarn is removed by burning.

Lose fibers protruding on the surface of textile products are chanted to remove them in the textile industry. This results in higher wet ability, better dyeing properties, enhanced reflection; no “frosty” appearance, a softer surface, good printing clarity, increased visibility of the fabric structure, less pilling, and reduced contamination by removing fluff and lint.

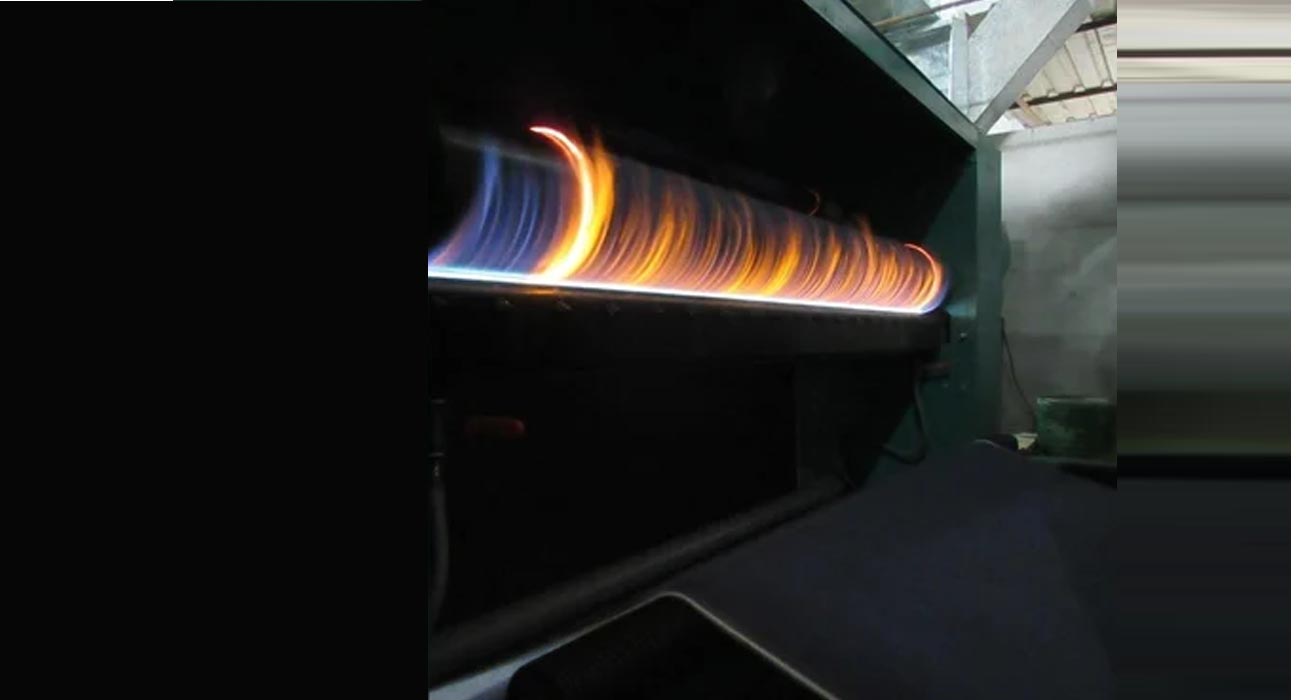

Usually, the mechanism is to pass one or both sides of fabric over a gas flame to burn off the protruding fibers. Other methods include infrared or heat for thermoplastic fibers. The singeing of yarns is called “gassing.” It’s usually the first step after weaving or knitting.

Objectives & Advantages of Singeing

- Singeing of fabric is done in order to obtain a clean fabric surface which allows the structure of the fabric to be clearly seen.

- Fabrics, which have been signed, soil-less easily than un-singed fabrics.

- The risk of pilling, especially with synthetics and their blends, is reduced in the case of singed fabrics.

- Singed fabrics allow the printing of fine intricate patterns with high clarity and detail.

- The risk of skittery dyeings with singed articles dyed in dark shades is considerably reduced, as randomly protruding fibers are removed in singeing which could cause diffused reflection of light.

The Necessity of Singeing in Textile

Singeing of textile materials is necessary for the following reasons:

- Cotton materials are valued for their smooth appearance. After the formation of fabric it has a fuzzy or hairy appearance due to projecting fibers; thus affecting the luster and smoothness cotton is known for.

- Unsigned fabrics are soiled easily

- The protruding fibers obstruct the subsequent dyeing and printing process

- Goods which are to be mercerized are signed to maximize the luster

- In fabrics of polyester and cellulosic fiber blends singeing is the best method to control pilling, sometimes double singeing is done to minimize the pilling.

Singeing Process

The singeing process is as follows:

- To produce a smooth surface finish on fabrics made from staple fibers first the fabric surfaces are brushed lightly to raise the unwanted fiber ends.

- Then the fabric is sung with or passed over heated copper plates or open gas flames. The fiber ends burn off.

- The fabric is moved very rapidly, and only the fiber ends are destroyed.

- As soon as the fabric leaves the singeing area, it enters a water bath or desizing bath. This stops any singeing afterglow or sparks that might damage the cloth.

Flow Chart of Singeing Process:

Batch

↓

↓

Pre –Brushing

↓

J-Scray

↓

Gas-singeing

↓

Post-Brushing

↓

Padding

↓

Squeezer

↓

Batching

References: