Lotus silk is one of the rarest fabrics in the world, produced only on small scale across Cambodia, Myanmar, and, more recently, Vietnam.

Extracting fibers from lotus stems has been in practice since 1910. Lotus and Silk yarns are blended to provide a unique striped fabric, organic and woven by hand following traditional Khmer techniques.

- Lotus silk is one of the rarest fabrics in the world.

- The threads need to be processed within 24 hours and so harvesting has to be done each day.

- Extracting enough lotus silk for one scarf can take two months.

EXCEPTIONAL PROPERTIES

- Lightweight

- Soft-touch

- Silky hand

- Especially breathable

- Wrinkle resistant

- Pilling resistance

- Tearing and tensile strength

Extraction Process of Lotus Silk Fiber

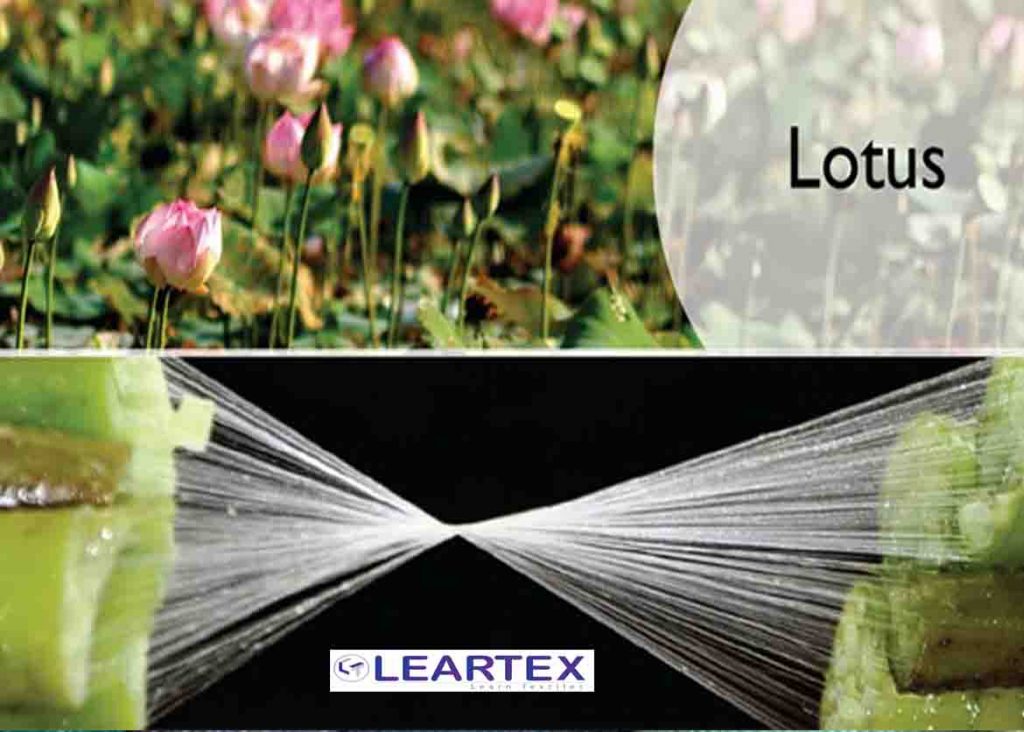

The entire process of fiber extraction, spinning it into yarn, and making the fabric is completely handmade making the processing time-consuming. This also limits the quantity of the fabric produced. Stems of the lotus plants are collected, cut, snapped, and twisted to expose its fibers.

These are thin and white filaments around 20 to 30 in number. These thin filaments are rolled into a single thread. Around 20-25 women are needed to extract fibers this way for one weaver to work with.

Fibers extracted from the stem are spun into yarn. Extracted fibers are placed in the skeins on a bamboo spinning frame preparing them for warping. Yarns are made by placing the fibers on a bamboo spinning frame and transferring the thread into winders for warping.

With much care, not to get tangles, threads are made; up to 40 meters long. The threads are then taken from the warping posts and are coiled into huge plastic bags. Yarns for the weft are wound into bamboo bobbins.

Fabrics are woven in the traditional Cambodian loom. Excess warp is stored and later released during the course of weaving. The woven fabric has a width of approximately 24 inches. During the process of weaving, threads are frequently moistened with water, as lotus fibers need to be kept cool. Around 1, 20,000 lotus stems are required to make fabrics adequate for making a costume.

The fibers are very delicate and should be woven within 24 hours of being extracted so as to prevent their deterioration.

HOW TO TAKE CARE OF BLENDED SILK FABRIC?

- Hand wash

- Do not bleach

- Dry flat in the shade

- Do not require iron

- Dry-clean: petroleum solvent only

References: