Kapok Fiber/Capok fiber is one of the natural cellulosic fibers which grow on the kapok plant. This fiber is also known as silk cotton because its natural luster is similar to that of pure silk. It is a seed Fiber. We will discuss the properties and uses of Kapok Fiber with the harvesting process in this article.

Physical Properties of kapok fiber:

- Average linear density – 0.064 tex

- Average diameter – 2.5 micrometer

- Average length – 20 mm

- Fineness – 0.4 – 0.6 denier

- Tenacity – 1.4 to 1.74 gm/den.

- Elongation at break -1.8 to 4.23

- Absorbency – kapok fiber has a high lumen percentage, because of this it has excellent oil absorbency and retention capacity.

- Lightweight – Capok fiber is 8 times lighter than cotton by volume

- Effect of acid – Capok fiber shows good resistance to acid and is not affected by acid.

- Effect of alkali – Capok fiber is not affected by alkali, which shows good resistance to alkali.

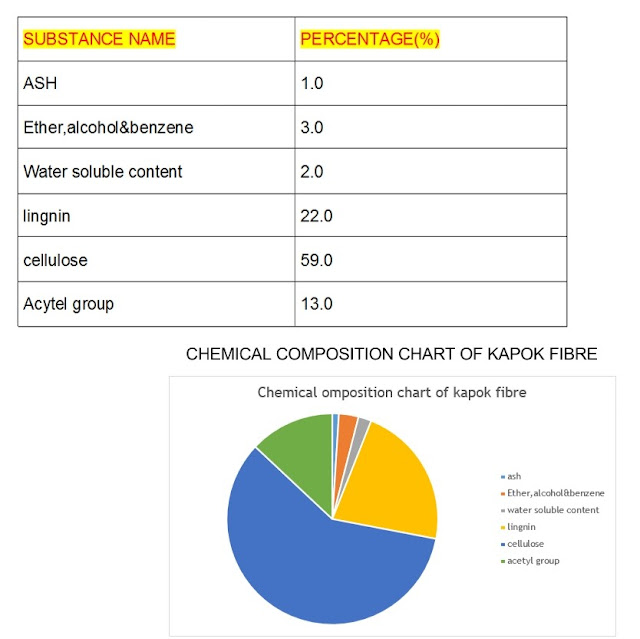

CHEMICAL COMPOSITION OF KAPOK FIBER:

The chemical composition is given below table:

Harvesting of Kapok Fiber

• Yield:

• Handling after harvest:

Uses of Kapok Fiber

INFORMATION ABOUT KAPOK TREE

• This tree can grow up to 100 meters high.

• This tree can be alive for 300 years.

• The trunks of kapok can be reached to 3 meters of diameter.

• Kapok tree doesn’t get damaged during kapok fiber harvesting.

• The kapok tree doesn’t require insecticides and artificial irrigation.

• It has the lowest specific gravity among all-natural fiber existing in the world.

• It has good insulating properties. In winter it keeps the warmth in, while in summer it prevents the heat.

• It is used for acoustic and thermal insulation.

- https://www.textileadvisor.com/2020/03/kapok-fibre-chemical-compositionand.html