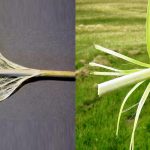

Natural and organic fibers become more and more popular these years. Hemp is a bast fiber plant-like jute, kenaf, flax, and ramie. Hemp fiber is one of the most environmentally friendly fiber.

These fibers are cellulosic fibers. Hemp fibers are one of the strongest and most durable among all of the natural textile fibers. This fiber shows similar properties like all of the natural bast fiber and excels in fiber length, durability, strength, absorbency, and mildew, and anti-microbial properties. We will discuss Hemp Fiber Properties and Uses with the Extraction Process.

Physical Properties of Hemp Fiber

|

Color:

|

The color of hemp fiber is yellowish-grey to deep brown. |

|

Length:

|

4 to 6.5% feet. |

| Tensile Strength: | Hemp is a very strong fiber. |

|

Elongation at break:

|

Hemp fibers stress easily. |

| Elastic Recovery: | Elastic recovery is very poor. It is less than linen fiber. |

|

Moisture Regain (MR %):

|

Standard moisture regain is 12%. It is more than cotton and linen. |

|

Effect of Heat:

|

Hemp fiber has excellent resistance to degradation by heat. |

| Effect of Sun Light: | It has enough ability to prevent the bad effect of sunlight. |

| Luster: | Highly bright like linen fiber. |

Chemical Properties of Hemp Fibers

| Effect Of Acid: | Hemp is attacked by hot dilute acids or cold concentrated acids which it disintegrates. Hemp fiber is destructed like cotton fiber in the action of acid. |

| Effects of Alkalis: | Hemp fiber has excellent resistance to alkalis. |

| The Effect of Organic Solvent: | It does not affect by the organic solvents. |

| Effects of Insects: | Hemp fiber is not attacked by moth-grubs or beetles. |

| Effect of Micro Organism: | Hemp fiber is attacked by fungi and bacteria. Mildews will feed on hemp fabric, rotting, and weakling the materials. Mildews and bacteria will flourish on hemp under hot and humid conditions. They can be protected by impregnation with certain types of chemicals. Copper Naphthenate is one of the chemicals. |

| Ability to Dye: | It is not suitable for dye hemp fiber. |

Extraction Process Of Hemp Fibers

Decortication– In this process, the de-leafed Hemp stems are then dried, i.e. conditioned and freed from the wood kernel in a sequence of a squeeze, break, and scutching processes.

Read: Types of Fabric Printing Method

Softening– By using a so-called Hemp softener or roller, the decorticated fibers are made softer and suppler.

Combing– The shortening of the initial fiber lengths from up to 3 m down to 650 mm is done on a special cutting machine. Then the short and tangled fibers are combed out, the long fibers are parallelized and smoothed using a hackling machine. In other words “hackling” (combing) means to remove any woody particles and to further align the fibers into a continuous “sliver” for spinning.

Spinning– After several drawing and doubling passages, the manufactured slivers are pre-spun roving yarns and according to quality and the desired yarn fineness, spun into Hemp yarn by wet or dry spinning processes.

Although as Hemp Fiber is coarser than Flax, the pins on the board for drafting the combed fiber into a sliver needed to be set differently. The rove produced was then boiled in caustic soda to refine it and most of the yarn was bleached with hydrogen peroxide. As it is similar to Flax fibers, generally the best yarns are obtained by wet spinning.

Uses of Hemp fiber

Coarse Hemp fibers and yarns are woven into cordage, rope, sacking, and heavy-duty tarpaulins. In Italy, fine hemp fibers are used for interior design and apparel fabrics. Hemp is used in tapestry, hats, shawls, rugs, posters, and towels.

Dyed hemp yarn from Hungary is suitable for rug weaving, placemats, crochet, and other craft items.

If You have any questions about Hemp Fiber Properties and Uses; leave a comment below.

References: