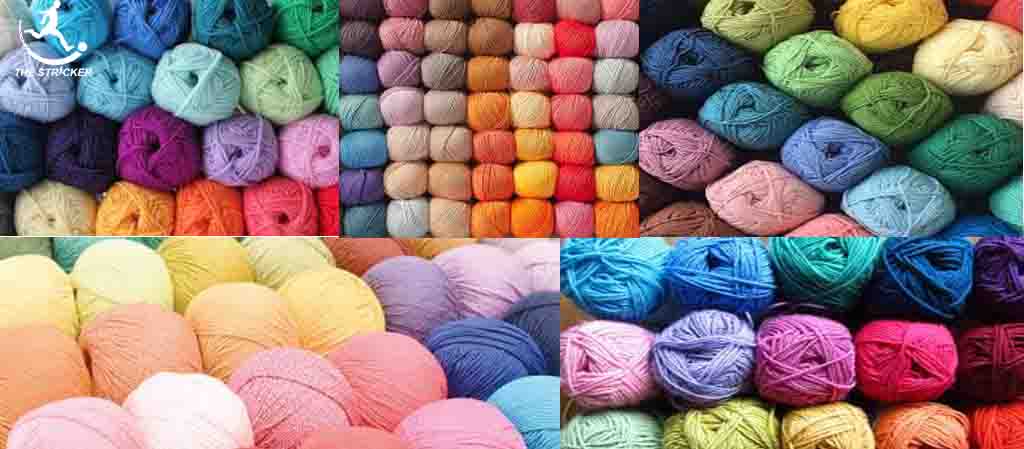

Yarn is a long continuous length of interlocked fibers, suitable for use in the production of Textile, Sewing, Knitting, or Weaving. We will discuss about the Types of Yarn in this article.

What is Yarn

Yarn may be defined as a linear assemblage of fibers or filaments formed into a continuous strand, having Textile characteristics. The Textile Characteristics are referred to as good tensile strength, high quality, etc.

The process of making yarn is called spinning. Yarn can be spun by machine or by hand. It is used for weaving tends to have a tight twist, smooth surface, and lots of lengthwise strength. Yarn for knitting has a looser twist.

Types of Yarn

Yarn can be classified according to:

1. Length of Fiber

- Spun Yarn

- short-staple

- long-staple

- Filament Yarn

- Mono Filament Yarn

- Multi Filament Yarn

2. Number of Strands

- Single Yarn

- Folded of double yarn

- Cable Yarn

3. Spinning System

- Ring Yarn

- Rotor Yarn

- Worsted Yarn

- Woolen Yarn

4. Types of Fiber Blend

- Single Fiber; For example

- Cotton Yarn

- Jute Yarn

- Nylon Yarn

- Polyester yarn

- Acrylic Yarn

- Multi Fiber

- P/C Yarn or T/C Yarn

- PV or TR etc.

5. Process Sequence Used

- Carded Yarn

- Combed Yarn

Length of Yarn

Spun Yarn?

Spun yarn is made by twisting staple fibers together to make a cohesive thread, or “single. Twisting fibers into yarn in the process called spinning can be dated back to the Upper Paleolithic, and yarn spinning was one of the very first processes to be industrialized.

Filament Yarn:

A filament yarn is made of one or more continuous strands called filaments with each component filament running the whole length of the yarn. Silk is the only major natural filament yarn. According to the shape of the filaments, filament yarns are classified into two types, flat and bulk.

Number of Strands

Single Yarn:

Single, or one-ply, yarns are single strands composed of fibers held together by at least a small amount of twist; or of filaments grouped together either with or without a twist. Also, narrow strips of material; or of single synthetic filaments extruded insufficient thickness for use alone as yarn.

Folded of double yarn:

This Yarn is created by twisting two or more yarns or single threads produces during twisting at the head for example on ring spinning machines. Twisting is done on a twisting machine where individual threads are twisted together by a ply twist.

Cable Yarn:

Cable Yarns or Cord yarns are produced by twisting ply yarns together, with the final twist usually applied in the opposite direction of the ply twist. This Cable cords may follow an SZS form, with S-twisted singles made into Z-twisted plies that are then combined with an S-twist, or may follow a ZSZ form.

You are reading about Types of Yarn

Spinning System

Ring Yarn:

Ring spinning is a method of spinning fibers, such as cotton, flax, or wool, to make a yarn. In-ring spinning, the roving is first attenuated by using drawing rollers, then spun and wound around a rotating spindle which in turn is contained within an independently rotating ring flyer.

Rotor Yarn:

Rotor yarn is formed by the twisting of the rotor by the rotor spinning machine. This yarn can be formed from the short fiber. Rotor yarn is also called open-end yarn & Rotor yarn is widely used yarns in Denim production.

Woolen Yarn:

Woolen (American English) or woolen (Commonwealth English) is a type of yarn made from carded wool. It is soft, light, stretchy, and full of air. This yarn is in contrast to worsted yarn, in which the fibers are combed to lie parallel rather than carded, producing a hard, strong yarn.

Worsted Yarn

Worsted is a high-quality type of wool yarn, the fabric made from this yarn, and a yarn weight category. The name derives from Worstead, a village in the English county of Norfolk.

Process Sequence Used

Carded Yarn:

The yarn which is made from short-staple and lower quality fiber is called Carded yarn. Mainly the name card come from a machine of spinning section. Carding is an operation that occurred in the spinning section. The yarn which is formed by carding operation is called carded yarn.

Combed Yarn:

Combed yarn is a yarn that has undergone a time-consuming combing process. The combing process makes its fibers straight and also ensures that the fibers run parallel to each other. The combing process makes the combed yarn more compact and strong. It should be noted here that, the combed yarn needs a higher cost than carded yarn.

Sources: